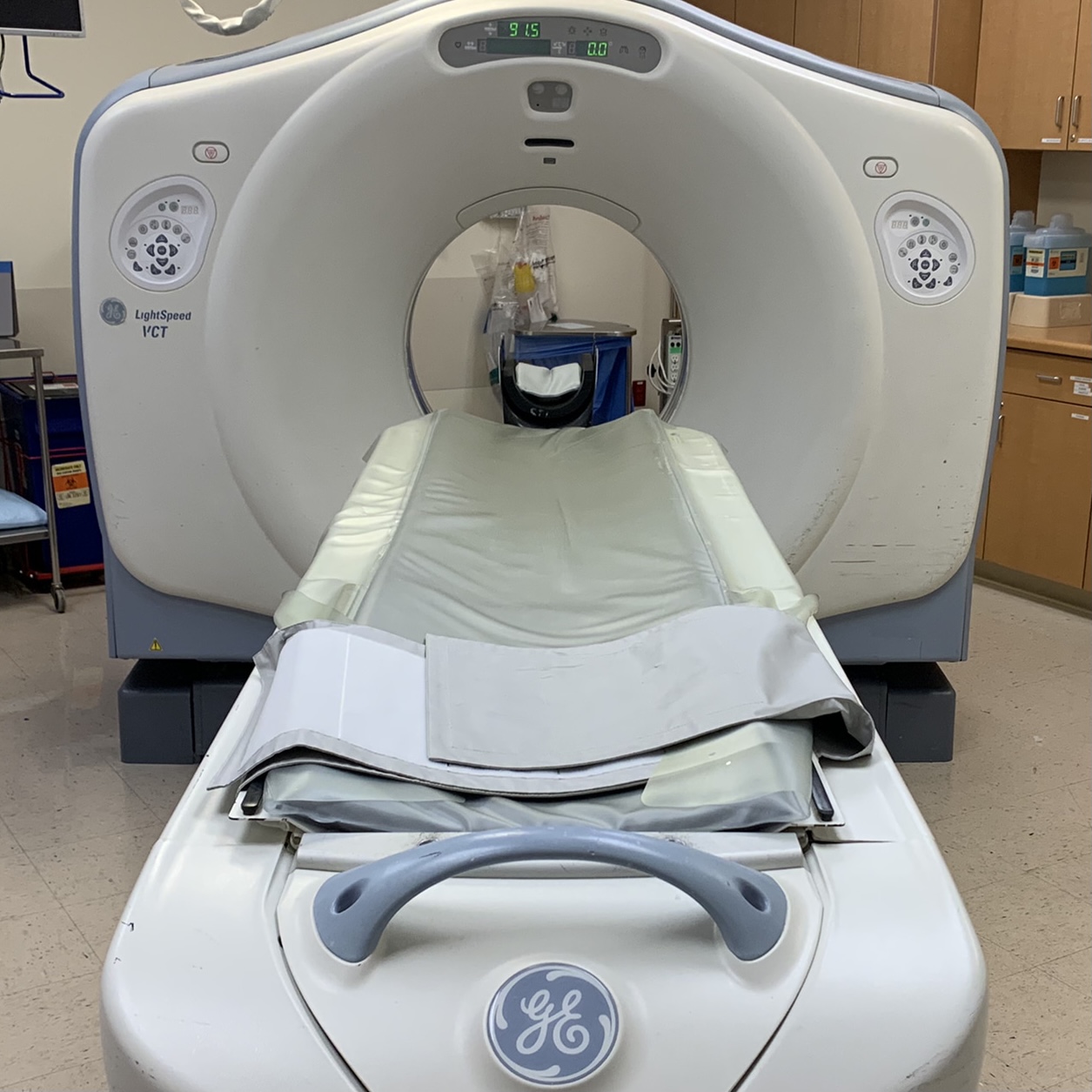

This page is a directory for resources related to GE Lightspeed VCT troubleshooting and repairs.

Skip the hours of troubleshooting and quickly resolve your issues with our step-by-step troubleshooting and solutions guides. You can find a link next to the error codes listed below (when available.)

This page is updated as new content is published, so check back often to stay up to date with the latest resources. Additionally, consider subscribing to our newsletter for the latest world-class resources.

- GE Lightspeed VCT 64 (32) Troubleshooting Overview

- GE Lightspeed VCT X-ray Gen Troubleshooting

- Tube Spits (30)

- Anode Rotation Errors (Code 40) GE Lightspeed VCT Troubleshooting

- Filament Heater Errors (Code 50) GE Lightspeed VCT Troubleshooting

- Code 50-0201h, 1201h

- Code 50-0202h, 1202h

- Code 50-0203h, 1203h

- Code 50-0204h, 1204h

- Code 50-0205h, 1205h

- Code 50-0206h, 1206h

- Code 50-0207h, 1207h

- Code 50-0208h, 1208h

- Code 50-0210h, 1210h

- Code 50-0211h, 1211h

- Code 50-0212h, 1212h

- Code 50-0213h, 1213h

- Code 50-0214h, 1214h

- Code 50-0215h, 1215h

- Code 50-0216h, 1216h

- Code 50-0217h, 1217h

- Code 50-0221h, 0222h, 0223h, 0224h, 1221h 1222h 1223h 1224h

- Code 50-0248h, 1248h

- Code 50-0249h, 1249h

- Exposure Errors (Code 60) GE Lightspeed VCT Troubleshooting

- Code 60-0306h

- Code 60-0307h

- Code 60-0308h

- Code 60-0309h

- Code 60-0310h

- Code 60-0311h

- Code 60-0312h

- Code 60-0313h

- Code 60-0314h

- Code 60-0316h

- Code 60-0317h

- Code 60-0318h

- Code 60-0319h

- Code 60-0320h

- Code 60-0321h

- Code 60-0323h

- Code 60-0325h

- Code 60-0326h

- Code 60-0329h

- Code 60-0401h

- Code 60-0402h

- Code 60-0403h

- Code 60-0451h

- Code 60-0504h

- Code 60-0801h

- Code 60-0802h

- Code 60-0803d

- Code 60-1181h

- Code 60-1407h

- Code 60-1408h

- Code 60-1409h

- Code 60-1410h

- Code 60-1411h

- Code 60-1420h

- Code 60-1421h

- Code 60-1454h

- Power Supply Errors (Code 70) GE Lightspeed VCT Troubleshooting

- Hardware Errors (Code 80) GE Lightspeed VCT Troubleshooting

- Code 80-0180h

- Code 80-0181h

- Code 80-0280h

- Code 80-0281h

- Code 80-0322h

- Code 80-03A0h

- Code 80-0601h

- Code 80-0602h

- Code 80-0902h

- Code 80-1000h

- Code 80-1006h

- Code 80-1010h

- Code 80-1180h

- Code 80-1182h

- Code 80-1280h

- Code 80-1281h

- Code 80-1402h

- Code 80-1403h

- Code 80-1404h

- Code 80-1413h

- Code 80-1414h

- Code 80-1415h

- Code 80-1416h

- Code 80-1417h

- Code 80-1418h

- Code 80-1419h

- Code 80-1422h

- Code 80-1422h

- Code 80-1425h

- Application Errors (Code 90) GE Lightspeed VCT Troubleshooting

- Communication Errors (Code 100) GE Lightspeed VCT Troubleshooting

- Thermal Errors (Code 110) GE Lightspeed VCT Troubleshooting

- Manipulation Errors (Code 120) GE Lightspeed VCT Troubleshooting

- Ingrid Errors (Code 130) GE Lightspeed VCT Troubleshooting

- Tube Switch Errors (Code 140) GE Lightspeed VCT Troubleshooting

- Conclusion

GE Lightspeed VCT 64 (32) Troubleshooting Overview

The following CT scanner troubleshooting section describes the error codes generated by CT scanner applications self-tests and diagnostics. Events can be tracked using the system error and message log. See the section below for more information about error reporting format.

Error log format: Simplified error code, generator phase, error class, error code, event timestamp, number of occurrences, current date and time.

| Error Code (General) | Description |

|---|---|

| 30 | Tube spits errors |

| 40 | Rotation errors |

| 50 | Heater errors |

| 60 | Exposure errors (HV inverter + mA measure + exposure control |

| 70 | Power supply errors (low voltage + DC bus) |

| 80 | Hardware errors (internal communications + cables) |

| 90 | Application errors (saved RAM + software) |

| 100 | External communication errors |

| 110 | Thermal errors |

| 120 | Manipulation Errors |

| 130 | Grid Errors / Not used on Jedi60DC. |

| 140 | Tube Switch Errors / Not used on Jedi60DC |

| 10 | Rotation warnings (engineering use) |

| 20 | Heater warnings (engineering use) |

| 25 | LVPS warnings (engineering use) |

| 27 | Application warnings (mainly saved RAM battery change) |

GE Lightspeed VCT X-ray Gen Troubleshooting

GE Lightspeed VCT X-ray generation error code descriptions, background and links to solutions guides.

Tube Spits (30)

Code 30-0305

Description

FPGA problem (Restarting safety)

Background

Error occurring on safety line while No root error present at the error inputs. Find additional details in the Code-0305 Lightspeed VCT Troubleshooting Guide.

Code 30-0324h data=1

Description

Tube spit (kV+ has dropped).

The generator sends only one message of error for all the spits (0324H) at the end of the exposure. During the same exposure we may have different kinds of spits. In the data of this error we can distinguish between the different spits:

1: Spit in anode side 2: Spit in cathode side 4: Spit in both sides 8: kV regulation error. For an exposure with anode and both sides spit, the data will be 5.

In case of KV regulation error , decrease kV-mA target of exposure (for example 60kV-50mA).

Background

kV drop/spit detected on Anode side

Code 30-0324h data=2

Description

Tube spit (kV- has dropped)

The generator sends only one message of error for all the spits (0324H) at the end of the exposure. During the same exposure we may have different kinds of spits. In the data of this error we can distinguish between the different spits:

1: Spit in anode side 2: Spit in cathode side 4: Spit in both sides 8: kV regulation error. For an exposure with anode and both sides spit, the data will be 5.

In case of KV regulation error , decrease kV-mA target of exposure (for example 60kV-50mA).

Background

kV drop/spit detected on cathode side

Code 30-0324h data=4

Description

Tube spit (kV+ and kV- dropped)

The generator sends only one message of error for all the spits (0324H) at the end of the exposure. During the same exposure we may have different kinds of spits. In the data of this error we can distinguish between the different spits:

1: Spit in anode side 2: Spit in cathode side 4: Spit in both sides 8: kV regulation error. For an exposure with anode and both sides spit, the data will be 5.

In case of KV regulation error , decrease kV-mA target of exposure (for example 60kV-50mA).

Background

kV drop/spit detected

Code 30-0324h data=8

Description

kV regulation error.

The generator sends only one message of error for all the spits (0324H) at the end of the exposure. During the same exposure we may have different kinds of spits. In the data of this error we can distinguish between the different spits:

1: Spit in anode side 2: Spit in cathode side 4: Spit in both sides 8: kV regulation error. For an exposure with anode and both sides spit, the data will be 5.

In case of KV regulation error , decrease kV-mA target of exposure (for example 60kV-50mA).

Background

This is a slow speed safety circuit in case of “smooth” spits or a case of a regulation problem.

Code 30-0328h

Description

Warning, spit counter overflow

Background

Find additional details in the Code 30-0328h GE Lightspeed VCT Troubleshooting Guide.

Code 30-0450h

Description

Tube Curr max detected

Background

Anode Rotation Errors (Code 40) GE Lightspeed VCT Troubleshooting

Code 40-0101h

Description

No CAN message received within 5 seconds.

Background

The rotation board has not received any signal from the PPC kV control main software for the last 5 sec., interpreted as a loss of communication

Code 40-0102h

Description

Data base not correct.

Background

The firmware of the rotation board has detected that the data base received from the PPC kV control board has wrong data.

Code 40-0103h

Description

Rotation current overload

Background

Rotation board has detected Main or auxiliary Rotation current too high compared to the max. Tube motor current.

Code 40-0104h

Description

Rotation current open load

Background

Rotation board detected that no current is flowing to the motor.

Code 40-0105h

Description

Rotation Phases unbalanced

Background

The amplitude difference of the current between main and auxiliary is too large.

Code 40-0106h

Description

Rotation phase error

Background

The Rotation board has detected that the current in the anode stator does not show the correct phase shift between main and auxiliary.

Code 40-0107h

Description

Rotation Inverter permanent over current

Background

An over current has been detected and 3 restart have been tried unsuccessfully within a single rotation state.

Code 40-0109h

Description

MAINS_DROP detected

Background

The firmware of the rotation board has detected the mains drop signal activation and transmitted error to PPC kV control

Code 40-0110h

Description

PRD error (reference Z3/Z4=bitmap)

Background

Firmware checksum, RAM test and EPLD access are performed at power up or reset.

| PRD Error- Z3/Z4 Bitmap |

|---|

| 0001H=RAM |

| 0002H=RAM stack |

| 0200H=EPLD |

| 8000H=program checksum |

Code 40-0111h

Description

F0 main frequency problem.

Background

EPLD has not applied the inverter start command.

Filament Heater Errors (Code 50) GE Lightspeed VCT Troubleshooting

Code 50-0201h, 1201h

Description

No CAN message received within 5 seconds

Background

The Heater board has not received any command from the PPC kV control main software for the last 5 sec., interpreted as a loss of communication

Code 50-0202h, 1202h

Description

Database not correct.

Background

The firmware of the heater board has detected that the data base received from the PPC kV control board has wrong data.

Code 50-0203h, 1203h

Description

Heater inverter permanent over current.(SW limit)

Background

Issued by the heater board when an over current has been detected and 3 restarts have been tried without success within 100 ms

Code 50-0204h, 1204h

Description

Filament permanent open circuit.

Background

Issued by the heater board when an open has been detected and 3 restarts have been tried without success within 100 ms

Code 50-0205h, 1205h

Description

Heater Inverter permanent short circuit (HW limit)

Background

Issued by the heater board when a short circuit has been detected and 3 restarts have been tried without success within 100 ms

Code 50-0206h, 1206h

Description

Filament overload Pre-Heat

Background

This is the result of an integrated value of the RMS current measurement on Heater board comparison with max. Tube value in database.

Code 50-0207h, 1207h

Description

Filament overload Boost

Background

This is the result of an integrated value of the RMS current measurement on Heater board comparison with max. Tube value in database.

Code 50-0208h, 1208h

Description

Filament overload Heat

Background

This is the result of an integrated value of the RMS current measurement on Heater board comparison with max. Tube value in database.

Code 50-0210h, 1210h

Description

PWM rate too low

Background

RMS filament current measurement (every 0.5 m sec.) on heater board is too low

Code 50-0211h, 1211h

Description

PWM rate too high

Background

RMS filament current measurement (every 0.5 msec.) on heater board is too high

Code 50-0212h, 1212h

Description

MAINS_DROP detected.

Background

The firmware of the Heater board has detected the mains drop signal activation and has transmitted error to PPC kV control

Code 50-0213h, 1213h

Description

PRD error (reference Z3/Z4=bitmap)

Background

Firmware checksum, RAM test and EPLD access are performed at power up or reset.

| PRD Error- Z3/Z4 Bitmap |

|---|

| 0001H=RAM |

| 0002H=RAM stack |

| 0200H=EPLD |

| 8000H=program checksum |

Code 50-0214h, 1214h

Description

Boost too long

Background

Boost command stayed longer than 400ms

Code 50-0215h, 1215h

Description

Filament selection error

Background

The relay on the Heater board selecting the filament is in the wrong position with respect to the selection

Code 50-0216h, 1216h

Description

Current feedback not null when inverter OFF

Background

Inverter current has been measured while the inverter was not commanded.

Code 50-0217h, 1217h

Description

Current not zero through a not selected filament

Background

Residual current of unselected filament at heater output (for Heater V6 version only)

Code 50-0221h, 0222h, 0223h, 0224h, 1221h 1222h 1223h 1224h

Description

Filament Database not correct

Background

The firmware of the heater board has detected that the Received Data base from PPC kV control contains erroneous data for Tube 1, 2, 3, or 4.

| Filament Database Error (Lightspeed VCT) |

|---|

| 2 bytes bitmap ( LSByte=small focus, MSByte=large focus) |

| Each bit points to an erroneous parameter |

Code 50-0248h, 1248h

Description

Heater large focus error

Background

The main software received an error from heater board with no error code associated

Code 50-0249h, 1249h

Description

Heater small focus error

Background

The main software received an error from heater board with no error code associated.

Exposure Errors (Code 60) GE Lightspeed VCT Troubleshooting

Code 60-0306h

Description

No kV feedback on anode side

Background

kV measured <12kV 0,5ms after start of exposure on anode side only

Code 60-0307h

Description

No kV feedback on cathode side

Background

kV measured <12kV 0,5ms after start of exposure on cathode side only

Code 60-0308h

Description

No kV Feedback (on anode and cathode)

Background

kV measured <12kV 0,5ms after start of exposure on both anode and cathode

Code 60-0309h

Description

kV detected during kV diagnostics.

Background

kV measured during inverter diagnostics while no kV must be generated.

Code 60-0310h

Description

kV MAX detected

Background

kV reached maximum kV limit during exposure

Code 60-0311h

Description

ILP current not OK.

Background

The current in the parallel resonant circuit of the inverter did not rise at the beginning of the exposure.

Code 60-0312h

Description

ILR current not OK

Background

The current in the serial resonant circuit of the inverter did not rise at the beginning of the exposure.

Code 60-0313h

Description

Inverter max. ILR current detected.

Background

This is a hardware detection of maximum current in serial resonant circuit.

Code 60-0314h

Description

ILR Current time out.

Background

The current resonant frequency is lower than expected

Code 60-0316h

Description

Spit Max error.

Background

PPC kV control has detected the number of tube spits during exposure has reached the limit (see theory of operation, software section)

Code 60-0317h

Description

Spit Ratio error.

Background

PPC kV control has detected the rate of tube spits during exposure has reached the limit (see theory of operation, software section)

Code 60-0318h

Description

kV did not reach 75% after 20ms.

Background

Indicates that there were no HV ON signal generated for exposure time count-up

Code 60-0319h

Description

kV unbalanced detected.

Background

Detects that there is more than 12kV difference between kV+ and kV –

Code 60-0320h

Description

FPGA problem; Safety hit with unknown reason

Background

No error at the inputs while checking for error source. Find additional details in the Code 60-0320h GE Lightspeed VCT Troubleshooting Guide.

Code 60-0321h

Description

Spit retry failed.

Background

Code 60-0323h

Description

ILP and ILR current not OK

Background

No inverter current measures at the beginning of the exposure

Code 60-0325h

Description

DSP overload

Background

Code 60-0326h

Description

DSP exposure stop

Background

FInd additional details in the Code 60-0326h GE Lightspeed VCT Troubleshooting Guide.

Code 60-0329h

Description

Wrong HV capa measure

Background

Code 60-0401h

Description

No mA feedback

Background

mA measurement function: PPC kV control has detected no mA feedback 20 ms after the beginning of the exposure.

Code 60-0402h

Description

mA scale error

Background

mA has been measured to be either too low or too high with respect to mA demand 20 ms after the beginning of the exposure.

Code 60-0403h

Description

mA out of range

Background

Measured mA every 50 msec exceeded 5% of mA demand. This error is logged, but does not stop the exposure.

Code 60-0451h

Description

mA meter saturated

Background

Find additional details in the Code 60-0451h GE Lightspeed VCT Troubleshooting Guide.

Code 60-0504h

Description

Inverter Gate Power Supply error

Background

Gate supply voltage has dropped below the level required to drive the IGBTs properly

Code 60-0801h

Description

Exposure backup mAs exceeded

Background

The exposure command last so long that the maximum mAs allowed has been reached

Code 60-0802h

Description

Exposure backup time exceeded.

Background

The exposure command last longer than the duration that was loaded by the system (Backup time + 5%.). Find additional details in the Code 60-0802h GE Lightspeed VCT Troubleshooting Guide.

Code 60-0803d

Description

Exposure command while generator not ready.

Background

Generator received an exposure command while not in ready state

Code 60-1181h

Description

mA between pulses

Background

Error found in verifying the counter normal operation.

Code 60-1407h

Description

mAs counter error

Background

Error found in verifying the counter normal operation.

Code 60-1408h

Description

AEC does not count.

Background

If there is no AEC feedback in AEC station exposure.

Code 60-1409h

Description

mAs meter saturated.

Background

A check is done on mAs counter operation at the beginning of exposure and found the mAs meter with unrealistic value. Find additional details in the Code 60-1409h GE Lightspeed VCT Troubleshooting Guide.

Code 60-1410h

Description

FPGA locked.

Background

FPGA detected an error and did not allow start exposure after exposure command signal was received. Find additional details in the Code 60-1410h GE Lightspeed VCT Troubleshooting Guide.

Code 60-1411h

Description

Time counter error.

Background

Error found in verifying the counter normal operation. Find additional details in the Code 60-1411h GE Lightspeed VCT Troubleshooting Guide.

Code 60-1420h

Description

Tomo cut too early

Background

Code 60-1421h

Description

Time cut instead tomo

Background

Generator received an exposure command while not in ready state

Code 60-1454h

Description

Jedi inverter temperature too high

Background

Power Supply Errors (Code 70) GE Lightspeed VCT Troubleshooting

Code 70-0501h

Description

DC bus out Of range (<400 or >850)

Background

Code 70-0502h

Description

Error Overvoltage > 780Vdc

Background

Code 70-0503h

Description

Inverter Gate Power Supply error (checked at prep)

Background

Code 70-0505h

Description

Mains power supply has dropped During exposure

Background

LVPS400 has detected a drop of its power supply and shuts down JEDI

Code 70-0506h

Description

DC bus 1 phase pre-charge error.

Background

Found DC bus did not reach 400V after 30 sec.Charge relay is not activated and pre-charge relay drops

Code 70-0507h

Description

DC bus 1 phase discharge error.

Background

Found that DC bus voltage is > 30 V before pre-charge.

Code 70-0510h

Description

HVPM AEC not 230V

Background

230V voltage generated in AEC board for ion chamber supply not OK

Code 70-0511h

Description

Error Undervoltage < 320VDC

Background

Code 70-0549h

Description

LVPS TRI: Unknown error

Background

The main software received a LVPS error with no error code associated

Code 70-0553h

Description

LVPS TRI: Detected +160V too high

Background

+160V is higher than 225V (measured on heater board)

Code 70-0557h

Description

LVPS TRI: Detected +160V too low

Background

+160V is lower than 110V (measured on heater board)

Code 70-0563h

Description

LVPS TRI: Detected +15V too high

Background

+15V is higher than 17.3V (measured on heater board)

Code 70-0567h

Description

LVPS TRI: Detected +15V too low

Background

+15V is lower than 13V (measured on heater board)

Code 70-0573h

Description

LVPS TRI: Detected -15V too high

Background

-15V is lower than -17.3V (measured on heater board)

Code 70-0577h

Description

LVPS TRI: Detected -15V too low

Background

-15V is higher than -13V (measured on heater board)

Hardware Errors (Code 80) GE Lightspeed VCT Troubleshooting

Code 80-0180h

Description

Rotation board communication problem.

Background

PPC kV control board communication Watch Dog with Rotation board popped up because it did not get reply from Rotation board.

Code 80-0181h

Description

Rotation board has reset.

Background

PPC kV control has detected the Rotation board has reset. PPC kV control will reload Rotation data base.

Code 80-0280h

Description

Heater 0 board communication problem

Background

PPC kV control board communication Watch Dog with Heater board popped up because it did not get reply from Heater board.

Code 80-0281h

Description

Heater board has reset.

Background

PPC kV control has detected the heater board has reset. KV ctrl will reload Rotation data base.

Code 80-0322h

Description

kV ref ADC / DAC failed

Background

PPC kV control DAC and ADC capability are permanently tested for coherency. Find additional details in the Code 80-0322h GE Lightspeed VCT Troubleshooting Guide.

Code 80-03A0h

Description

DSP error

Background

DSP program corrupted. Find additional details in the Code 80-03A0h GE Lightspeed VCT Troubleshooting Guide.

Code 80-0601h

Description

RTL error (+ associated data to check which of the 4 RTL lines)

Background

Real Time Lines show a wrong state. RTL’s are tested on a regular basis in stand by.

Code 80-0602h

Description

External CAN bus off

Background

Communication to system through CAN not possible. System will report JEDI comm. problem.

Code 80-0902h

Description

Tube Fan supply error.

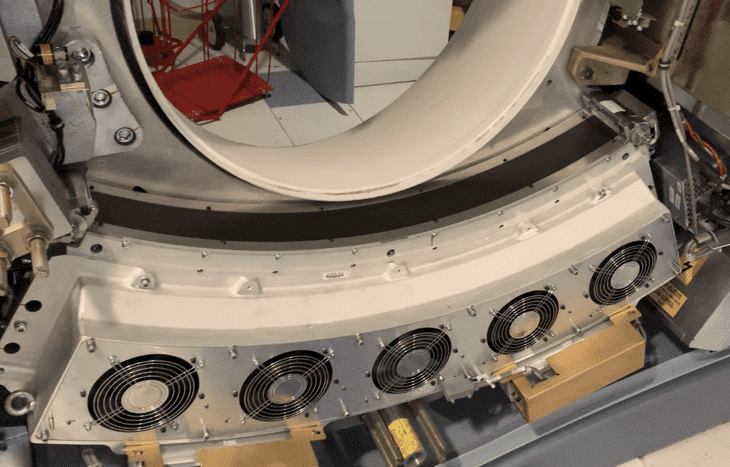

Background

Rotation board has detected that a wrong voltage is applied to the tube fan

Code 80-1000h

Description

Tube switch com. Problem

Background

Code 80-1006h

Description

Background

Code 80-1010h

Description

Tube Switch comm problem

Background

Code 80-1180h

Description

Ingrid not active

Background

Code 80-1182h

Description

Ingrid CAN bus off

Background

Code 80-1280h

Description

Heater 1 board communication problem

Background

Code 80-1281h

Description

Heater 1 board has reset

Background

Code 80-1402h

Description

Internal CAN bus off

Background

CAN device on PPC kV control board detected abnormal level on it’s 2 line and sent error to the CPU

Code 80-1403h

Description

Connection Fault

Background

One of the flat cable connector is not connected in Generator.

Code 80-1404h

Description

FPGA configuration problem.

Background

Detected during power up. The PPC kV control main software cannot load the FPGA. Find additional details in the Code 80-1404h GE Lightspeed VCT Troubleshooting Guide.

Code 80-1413h

Description

Internal CAN bus Txo

Background

Internal CAN bus not transmitting. Find additional details in the Code 80-1413h GE Lightspeed VCT Troubleshooting Guide.

Code 80-1414h

Description

Internal CAN LD bus Txo

Background

Internal LD CAN bus not transmitting

Code 80-1415h

Description

External CAN bus Txo

Background

External CAN bus not transmitting. System to JEDI communication not possible

Code 80-1416h

Description

Internal CAN RTL2 error

Background

Code 80-1417h

Description

DC disch. when inhib

Background

Code 80-1418h

Description

No DC disch. on request

Background

Code 80-1419h

Description

10V reference error

Background

Find additional details in the Code 80-1419h GE Lightspeed VCT Troubleshooting Guide.

Code 80-1422h

Description

Overpress or Blown fuse

Background

Code 80-1422h

Description

H4 Power IF com. error

Background

Code 80-1425h

Description

Rotor accel is forbidden

Background

Application Errors (Code 90) GE Lightspeed VCT Troubleshooting

Code 90-0701h

Description

NV RAM checksum pb.

Background

Generator PPC kV control board has detected corruption in the NV Ram verification (After power up)

Code 90-0702h

Description

Software problem.

Background

Find additional details in the Code 90-0702h GE Lightspeed VCT Troubleshooting Guide.

Code 90-0705h

Description

System or database configuration error.

Background

The identifier of the system and the database are not compatible.

Code 90-0706h

Description

Wrong DSP version

Background

(Engineering debug). Find additional details in the Code 90-0706h GE Lightspeed VCT Troubleshooting Guide.

Code 90-0707h

Description

Wrong FPGA version

Background

(Engineering debug). Find additional details in the Code 90-0707h GE Lightspeed VCT Troubleshooting Guide.

Code 90-1001h

Description

Wrong tube number selection

Background

Code 90-1003h

Description

Tube Sel. while rotor On

Background

Code 90-1004h

Description

Tube Sel. while heat On

Background

Code 90-1005h

Description

Tube Sel while kV On

Background

Code 90-1011h

Description

Unexpected tube switch board

Background

A switch board has been detected in a single tube system

Code 90-1012h

Description

Exposure preparation while tube not ready (during tube switching)

Background

Communication Errors (Code 100) GE Lightspeed VCT Troubleshooting

Code 100-0603h

Description

Debug screen com. error

Background

Code 100-0604h

Description

Database download error

Background

Generator has detected a problem during data base download

Code 100-0605h

Description

TAV communication error.

Background

Generator has detected a communication problem between the I/F and the service laptop (When Generator is controlled by the laptop).

Code 100-1301h

Description

AEC Board com problem.

Background

AEC communication problem

Code 100-1302h

Description

Watchdog CAN com. Error

Background

No more communication with system

Thermal Errors (Code 110) GE Lightspeed VCT Troubleshooting

Code 110-0804h

Description

Tank Thermal sensor too high

Background

HV tank temperature has reached the maximum limit.

Code 110-0805h

Description

Inverter HW temperature too high.

Background

Parallel inductor temperature has reached the maximum limit.

Code 110-0806h

Description

Lp temperature too high

Background

Lp inductor temperature has reached the maximum limit

Code 110-0903h

Description

Tube exceeded 70°C

Background

Tube temperature switch detected open

Code 110-0904h

Description

HEMIT Thermal error.

Background

Code 110-0905h

Description

Tube thermal protection

Background

Thermal protection algorithm has detected that tube exceeded its temperature limits

Code 110-0906h

Description

Tube track protection

Background

For pulsed mode only , instantaneous exceeding tube capacity

Code 110-1405h

Description

Tank temperature sensor too low

Background

HV tank temperature is below < 3°C. Indicates sensor malfunction

Code 110-1406h

Description

Inverter HW temp meas too low

Background

Parallel inductor temperature is below < 3°C. Indicates sensor malfunction

Code 110-1412h

Description

Lp temperature too low

Background

Manipulation Errors (Code 120) GE Lightspeed VCT Troubleshooting

Code 120-1500h

Description

Tomo brightness not good

Background

Code 120-1501h

Description

Release exposure switch

Background

Code 120-1502h

Description

AEC does not cut exposure Exposure stopped by mAs limitation

Background

Ingrid Errors (Code 130) GE Lightspeed VCT Troubleshooting

Code 130-1100h

Description

Ingrid communication watchdog error

Background

Communication lost

Code 130-1101h

Description

Ingrid repetition rate higher than 100 fps

Background

Code 130-1102h

Description

Inter grid CMD time shorter than 0.5ms

Background

Code 130-1103h

Description

Ingrid power supply voltage lower than 130V

Background

Code 130-1104h

Description

Ingrid power supply voltage higher than 200V

Background

Code 130-1105h

Description

Ingrid feedback error

Background

Ingrid voltage is wrong

Code 130-1107h

Description

Grid feedback voltage too High

Background

Code 130-1109h

Description

Bias feedback voltage too High

Background

Code 130-1110h

Description

Ingrid target DAC voltage feedback fault

Background

Code 130-1199h

Description

Ingrid error

Background

Tube Switch Errors (Code 140) GE Lightspeed VCT Troubleshooting

Code 140-1020h

Description

Tube Switch status error

Background

Code 140-1021h

Description

Tube Switch State Machine error

Background

Code 140-1022h

Description

Tube Switch lamp relay feedback error

Background

Code 140-1023h

Description

Tube Switch heater SF feedback error

Background

Code 140-1024h

Description

Tube Switch heater LF feedback error

Background

Code 140-1025h

Description

Tube Switch rotation relay feedback error

Background

Code 140-1026h

Description

Tube Switch Motor Position error

Background

(Motor is in intermediate position)

Code 140-1027h

Description

Tube Switch Motor Feedback error

Background

(Switching Time out)

Code 140-1028h

Description

Tube Switch Motor is in the opposite position

Background

Code 140-1030h

Description

Tube switch config reply error

Background

Code 140-1031h

Description

Tube switch status reply error

Background

Code 140-1032h

Description

Tube switch motor move refused

Background

Code 140-1033h

Description

Tube switch rotor capa activation error

Background

Technical Support and On-Site Repair Services Available

When your CT scanner is down, every minute matters.

Conclusion

MRIPETCTSOURCE provides the best radiology resources to assist your GE Lightspeed VCT troubleshooting and repairs. New resources will be linked to this page as they are published so check back often for the latest CT scan machine troubleshooting resources.

Are you interested in seeing a solutions guide? Sign up for our newsletter to be notified when we release step-by=step troubleshooting guides.

Related Resources

- GE Lightspeed VCT Troubleshooting Guides

- GE Lightspeed VCT Parts List

- GE Lightspeed VCT Directory and Information Page

- Field Engineers Resources

- Technologist Resources Page

Click here to view the CT Scanner Service Resources playlist.